Description

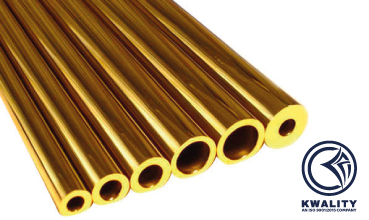

Also known as cartridge brass, spinning brass, spring brass. C26000, 70/30 Brass and C26130, Arsenical brass, have excellent ductility and strength, and are the most widely used brasses. Arsenical brass contains a small addition of arsenic, which greatly improves corrosion resistance in waters, but is otherwise effectively identical. These alloys have the distinctive bright yellow colour normally associated with brass. They have the optimum combination of strength and ductility in the copper-zinc alloys, coupled with good corrosion resistance.

C26000 is used for architecture, drawn and spun containers and shapes, electrical terminals and connectors, door handles, plumbers hardware. C26130 is used for tube and fittings in contact with water, including potable water. Typical applications include: Architecture, grillwork, appliances, drawn & spun containers and components, radiator cores and tanks, electrical terminals, plugs and lamp fittings, locks, door handles, name plates, plumbers hardware, fasteners, cartridge cases, cylinder liners for pump. Available forms in Metals can supply this alloy as coil, sheet, plate, rods, bars, sections.

Corrosion Resistance of Brass and Arsenical Brass Alloy C26000 has good corrosion resistance to weathering and very good resistance to many chemical. It may undergo dezincification in stagnant or slowly moving salt solutions, brackish water or acidic solutions. Although it will resist most waters, C26130 is preferred as it contains a small arsenic addition which inhibits corrosion.

C26000 should not be used in contact with ammonia or ammonia compounds, as it may suffer stress corrosion cracking. Beware of corrosion inhibitors in piping systems containing carbon steel, which should be checked for compatibility with alloy C26000. 70/30 brass should not be used with acetic acid, acetylene, brines, calcium chloride, moist chlorine, chromic acid, hydrochloric acid, mercury or its compounds, nitric acid and sodium hypochlorite.

Application

Chemical Composition

| Elements | ||||

|---|---|---|---|---|

| Cu(1) | Pb | Zn | Fe | |

|

(1) Cu + Sum of Named Elements 99.7% min. |

||||

| Min (%) | 68.5 | |||

| Max (%) | 71.5 | 0.07 | Rem | 0.05 |

Mechanical Properties

| Form | Temper | Temper Code | Tensile Strength (ksi) |

YS-0.5% Ext (ksi) |

Elongation (%) |

Rockwell B scale | Rockwell F scale | Rockwell 30T scale | Shear Strength (ksi) |

Torsion Modulus (ksi) |

Fatigue Strength** (ksi) |

Section Size (in) |

Cold Work (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| * Measured at room temperature, 68°F (20°C). ** Fatigue Strength: 100 x 106 cycles, unless indicated as [N] x 106. | |||||||||||||

| Flat Products | 1/2 Hard | H02 |

62 Typ |

25 Typ |

70 Typ |

65 Typ |

40 Typ |

18 Typ | 0.04 | ||||

| 1/4 Hard | H01 |

54 Typ |

40 Typ |

43 Typ |

55 Typ |

54 Typ |

36 Typ |

0.04 | |||||

| Extra Hard | H06 |

86 Typ |

65 Typ |

5 Typ |

88 Typ |

76 Typ |

46 Typ |

0.04 | |||||

| Extra Spring | H10 |

99 Typ |

65 Typ |

3 Typ |

93 Typ |

78 Typ |

0.04 | ||||||

| Hard | H04 |

76 Typ |

63 Typ |

8 Typ |

82 Typ |

73 Typ |

44 Typ |

21 Typ | 0.04 | ||||

| Nominal Grain Size 0.015 mm | OS015 |

53 Typ |

22 Typ |

54 Typ |

78 Typ |

43 Typ |

35 Typ |

14 Typ | 0.04 | ||||

| Nominal Grain Size 0.025 mm | OS025 |

51 Typ |

19 Typ |

55 Typ |

72 Typ |

36 Typ |

0.04 | ||||||

| Nominal Grain Size 0.035 mm | OS035 |

49 Typ |

17 Typ |

57 Typ |

68 Typ |

31 Typ |

34 Typ |

14 Typ | 0.04 | ||||

| Nominal Grain Size 0.050 mm | OS050 |

47 Typ |

15 Typ |

62 Typ |

64 Typ |

26 Typ |

0.04 | ||||||

| Nominal Grain Size 0.070 mm | OS070 |

46 Typ |

14 Typ |

65 Typ |

58 Typ |

15 Typ |

32 Typ |

13 Typ | 0.04 | ||||

| Nominal Grain Size 0.100 mm | OS100 |

44 Typ |

11 Typ |

66 Typ |

54 Typ |

11 Typ |

13 Typ | 0.04 | |||||

| Spring | H08 |

94 Typ |

65 Typ |

3 Typ |

91 Typ |

77 Typ |

48 Typ |

23 Typ | 0.04 | ||||

| Rod | 1/2 Hard | H02 |

70 Typ |

30 Typ |

80 Typ |

42 Typ |

22 Typ | 1 | 20 | ||||

| 1/8 Hard | H00 |

55 Typ |

40 Typ |

48 Typ |

60 Typ |

36 Typ |

5.8 Typ | 1 | 6 | ||||

| Nominal Grain Size 0.050 mm | OS050 |

48 Typ |

16 Typ |

65 Typ |

65 Typ |

34 Typ |

1 | ||||||

| Tube | Hard Drawn | H80 |

78 Typ |

8 Typ |

82 Typ |

73 Typ |

35 | ||||||

| Nominal Grain Size 0.025 mm | OS025 |

52 Typ |

20 Typ |

55 Typ |

75 Typ |

40 Typ |

|||||||

| Nominal Grain Size 0.050 mm | OS050 |

47 Typ |

15 Typ |

65 Typ |

64 Typ |

26 Typ |

|||||||

| Wire | 1/4 Hard | H01 |

70 Typ |

20 Typ |

0.08 | ||||||||

| 1/8 Hard | H00 |

58 Typ |

35 Typ |

38 Typ |

0.08 | ||||||||

| Extra Hard | H06 |

124 Typ |

4 Typ |

0.08 | |||||||||

| Nominal Grain Size 0.015 mm | OS015 |

54 Typ |

56 Typ |

0.08 | |||||||||

| Nominal Grain Size 0.025 mm | OS025 |

52 Typ |

58 Typ |

0.08 | |||||||||

| Nominal Grain Size 0.035 mm | OS035 |

50 Typ |

60 Typ |

34 Typ |

0.08 | ||||||||

| Nominal Grain Size 0.050 mm | OS050 |

48 Typ |

64 Typ |

0.08 | |||||||||

| Spring | H08 |

130 Typ |

3 Typ |

60 Typ |

22 Typ | 0.08 | |||||||

Physical Properties

| Melting Point - Liquidus°F | 1750 |

|---|---|

| Melting Point - Solidus°F | 1680 |

| Densitylb/cu in. at 68°F | 0.308 |

| Specific Gravity | 8.53 |

| Electrical Conductivity% IACS at 68°F | 28 |

| Thermal ConductivityBtu/ sq ft/ ft hr/ °F at 68°F | 70 |

| Coefficient of Thermal Expansion 68-57210 to -6 power per °F (68 – 572°F) | 11.1 |

| Specific Heat CapacityBtu/ lb /°F at 68°F | 0.09 |

| Modulus of Elasticity in Tensionksi | 16000 |

| Modulus of Rigidityksi | 6000 |

Fabrication Properties

| Technique | Suitability |

|---|---|

| Soldering | Excellent |

| Brazing | Excellent |

| Oxyacetylene Welding | Good |

| Gas Shielded Arc Welding | Good |

| Coated Metal Arc Welding | Not Recommended |

| Spot Weld | Fair |

| Seam Weld | Not Recommended |

| Butt Weld | Good |

| Capacity for Being Cold Worked | Excellent |

| Capacity for Being Hot Formed | Fair |

| Machinability Rating | 30 |

Thermal Properties

| Treatment | Minimum* | Maximum* | ||

|---|---|---|---|---|

| * Temperature is measured in Fahrenheit. | ||||

| Annealing | 800 | 1400 | ||

| Hot Treatment | 1350 | 1550 | ||