Description

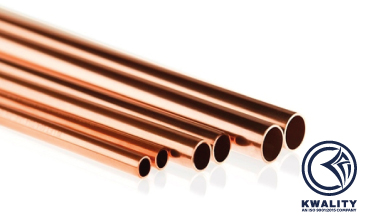

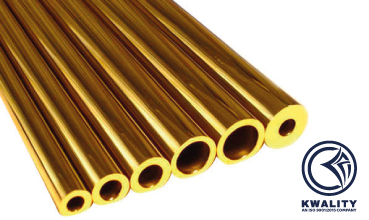

Copper Nickel 70/30 Pipes exhibits very high chloride ion corrosion crack resistance. This means the pipes could last longer under sea water and marine environments. The Cuni 70/30 Seamless Pipes contains 70% copper and 30% nickel. The addition of nickel allows the 70/30 Copper Nickel Pipes to be stronger than the pure copper grades and allows the pipe to be ductile. The copper material is easy to weld with. The addition of iron and manganese in the Cu Ni 70 30 Pipes material makes it possible for easy welding. There are different classes of cupronickel pipes that are used in different industries. The B466 C71500 Pipe is a variation of the 70/30 material that is used especially in marine and seawater applications. The copper nickel pipes are used in seamless or welded conditions.

The seamless pipes are good for precision applications whereas the welded pipes are stronger. The ASTM B111 Copper Nickel 70/30 Welded Pipes could be used in piping in ships and marine systems. Because the material avoids biofouling, a process which accumulates live organisms, it is preferred in boats, ships and marine equipment which need to be clean. The Copper Nickel 70/30 Hollow Pipes are one of the most used type of cupronickel pipes. The Eemua 144 Cuni 70/30 Pipes are used especially in the boat hulls and ship piping. There are different shapes such as round, square, rectangular and hexagonal pipes but the round shape is the most commonly used. The 70/30 Copper Nickel Square Pipes are used in applications where strength is inevitable and corrosion resistance is also needed. The ASTM B466 Cupro Nickel 70/30 Round Pipes are used in boilers, condensers and heat exchangers. There are special cases such as the DIN 2.0882 Copper Nickel 70/30 Beveled End Pipes and with different schedules such as the Schedule 40 Copper Nickel 70/30 Pipes.

Application

Specifications

| Schedule Standard and Specification | ASTM B 466 ASME SB 466 / ASTM B 467 ASME SB 467 |

| Dimensions | ASME B36.10M or B36.19M |

| Ranging in size from | 1/2 " - 6" IN OD & NB IN Various SWG & SCH |

| Basic types | Seamless / ERW / Welded / Fabricated |

| Shapes | Round, Hydraulic, square, hollow |

| Pipe End Beveling | Treaded Both Ends, Beveled end, Bevel both ends, Beveled One End, Bevel one end, Plain Both Ends, Treaded One End, Plain One End, Bevel large end, Bevel small end |

| UNS | C71500 |

| WERKSTOFF NR. | 2.0882 |

| Melting Point | 2260 F |

Chemical Composition

| Cu-Ni 70/30 | Cu | Pb | Mn | Fe | Zn | Ni |

| 65.0 min | 0.05 max | 1.0 max | 0.4-1.0 | 1 max | 29 – 33 |

Mechanical Properties

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 0.323 lb/in3 at 68 F | 2260 F | 20000 psi | 50000 psi | 30 % |

Size Chart of UNS C71500

| Wall | Sizes ( O.D.) |

|---|---|

| .010 | 1/16" , 1/8" , 3/16" |

| .020 | 1/16" , 1/8" , 3/16" , 1/4" , 5/16" , 3/8" |

| .012 | 1/8" |

| .016 | 1/8" , 3/16" |

| .028 | 1/8" , 3/16" , 1/4" , 5/16" , 3/8" , 1/2" , 3/4" , 1" , 1 1/2" , 2" |

| .035 | 1/8" , 3/16" , 1/4" , 5/16" , 3/8" , 7/16" , 1/2" , 16" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 1 5/8" , 2" , 2 1/4" |

| .049 | 3/16" , 1/4" , 5/16" , 3/8" , 1/2" , 16" , 5/8" , 3/4" , 7/8" , 1" , 1 1/8" , 1 1/4" , 1 1/2" , 1 5/8" , 2" , 2 1/4" |

| .065 | 1/4" , 5/16" , 3/8" , 1/2" , 16" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 1 5/8" , 1 3/4" , 2" , 2 1/2" , 3" |

| .083 | 1/4" , 3/8" , 1/2" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 1 5/8" , 1 7/8" , 2" , 2 1/2" ,3" |

| .095 | 1/2" , 5/8" , 1" , 1 1/4" , 1 1/2" , 2" |

| .109 | 1/2" , 3/4" , 1" , 1 1/4" , 1 1/2" , 2" |

| .120 | 1/2" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 2" , 2 1/4" , 2 1/2" , 3" |

| .125 | 3/4" , 1" , 1 1/4" , 1 1/2" , 2" , 3" , 3 1/4" |

| .134 | 1" |

| .250 | 3" |

| .375 | 3 1/2" |

Technical Specification of Copper Nickel C71500

| Standard | BS 2871 PART 3 | ASTM B-111 | DIN 1785 | NFA 51 102 | JIS H3300 | IS 1545 |

| Symbol | CN 107 | C 71500 | CuZn30 Mn 1 Fe | CuZn30 Mn 1 Fe | C 7150 | CuNi 30 Mn 1 Fe |

| Cu | Remainder | Remainder | Remainder | Remainder | Remainder | Remainder |

| Pb | 0.01 | 0.05 | 0.03 | 0.05 | 0.05 | 0.05 |

| Sn+Pb | ||||||

| Ni | 30.00 - 32.00 | 29.0 - 33.0 | 30.0-32.0 | 29.0 - 32.0 | 29.0 - 33.0 | 29.0 - 33.0 |

| Fe | 0.4 - 1.0 | 0.4 - 1.0 | 0.4 - 1.0 | 0.4 - 0.7 | 0.4 - 0.7 | 0.4 - 1.0 |

| Mn | 0.5-1.0 | 1.0 | 0.5 - 1.5 | 0.5 - 1.5 | 0.2 - 1.0 | 0.5 - 1.0 |

| S | 0.05 | - | 0.05 | 0.02 | - | - |

| C | 0.06 | - | 0.30 | 0.10 | - | 0.30 |

| Total Impurities Max. | 0.30 | - | 0.10 | 0.30 | Rem (Cu+Ni+Fe+Mn 99.5 Min) | 0.30 |

| Condition | M | O 61 | F 37 | - | O | O |

| F 42 | ||||||

| O | HR 50 | D | ||||

| Yield | - | 125 Min | 120

- 220 150 - 260 |

- | - | - |

| Strength | - | 345 Min | ||||

| N/mm2 | ||||||

| Tensile | - | 360 Min | 370 Min | - | 363 Min | 360 Min |

| N/mm2 | - | 495 Min | 420 Min | - | - | 480 Min |

| Elongation | - | 12/15* | 35 Min | - | 30 Min | - |

| % | - | - | 30 Min | - | ||

| Hardness HV 5 | 150 | - | - | 90 - 130 | - | 115 Max |

| 90-120 | 140 Min | |||||

| Grain Size | 0.05 Max | - | - | 010 - 045 | 010 - 045 | - |

| Mm (75X) |