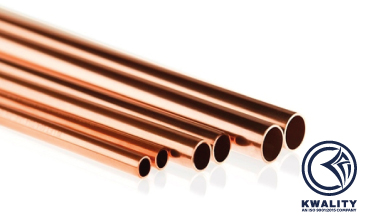

The copper tube we manufacture finds numerous applications in Heating and Solar Panels. For steam-heating systems, especially return lines, the outstanding corrosion resistance and non-rusting characteristics of copper tube assure trouble-free service and maintenance of traps, valves and other devices.

A modern application of an ancient principle, radiant panel heating, can be used successfully in nearly all types of structures. In panel systems, low-temperature hot water, circulating through coils or grids of copper tube embedded in a concrete floor or plaster ceiling, warms the surfaces and the air. Panel systems offer uniform heating and comfort, an invisible heat source, complete use of the floor area, cleanliness and the elimination of dust-carrying drafts.

Listed below are the properties of the Copper tubes manufactured by us that are ideal for heating applications -

|

Physical Properties: |

||||||

| Temper | Tensile strength Kg/mm2 Min. | Elongation % on 5.65 A Min. | ||||

| Annealed | 21.5 | 33 | ||||

| As Manufactured | 23.5 | 13 | ||||

|

Chemical Requirements: |

|||||

| Copper (Incl. Silver) | 99.85% Min. | ||||

| Phosphorus | 0.013 to 0.05% | ||||

| Total Impurities | 0.06% Max. | ||||

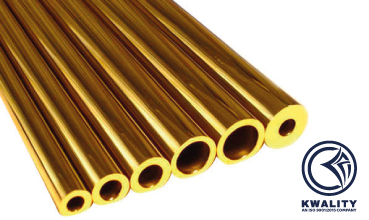

Today's focus on energy and resource efficiency as well as sustainable construction has created a global inertia for the use of solar thermal heating and cooling for both space-conditioning and water heating. In many ways, this parallels the national commitment to use solar energy spawned by the energy crises in the 1970s. Solar energy systems to heat domestic water and for space heating are based on adding a collector to the heating system to capture energy from the sun. In general, this simply involves extending the heating/plumbing system to the roof of the house, where a solar collector is incorporated into it.

Copper is the logical material for solar energy systems because:

Copper's thermal advantages mean thinner copper sheet can collect the same heat as much thicker gages of aluminum or steel sheet, and copper collector tubes can be more widely spaced.

Copper's resistance to atmospheric corrosion is well demonstrated by its service in roofing and flashing. Unless attacked by the sulfur or nitrogen oxide exhausts from utilities or process industries, copper has withstood decades—even centuries—of weathering.

Copper resists hot water corrosion equally well. Properly sized to keep flow rates below those recommended in Pressure System Sizing, and properly installed, copper hot water systems are, for all practical purposes, completely resistant to corrosion.

The ease with which copper plumbing systems are joined by soldering needs no special emphasis. Sheet copper fabrication is equally recognized for its ease and simplicity.