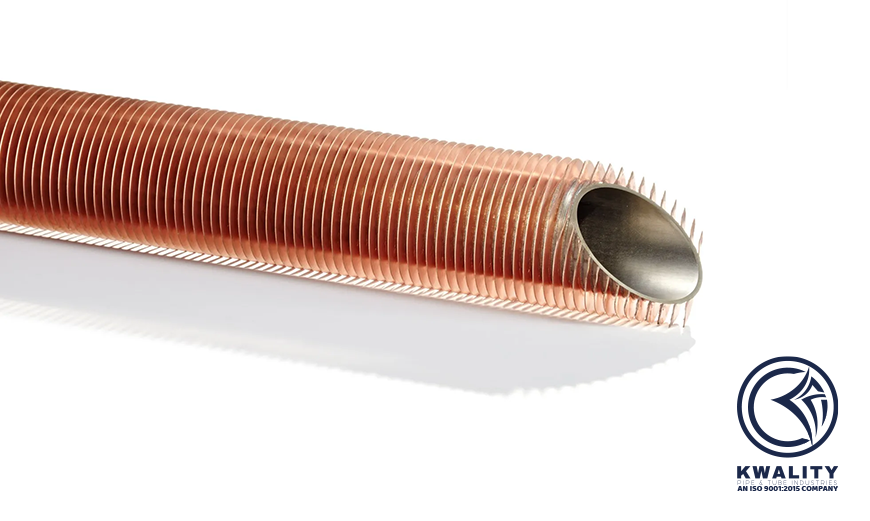

Turbo-Chill Tubes

Turbo-Chill tubes is a speciality item designed as one of the variety of Integral Low Finned Tubes. These tubes are designed for various Freezing machines as a high performance heat transfer tube. TURBO CHILL tubes are basically Integrally Finned Tubes with Internal Grooves or spiral ridges on the internal surface of the tube wall. This design of the tube remarkably increases the inside fluid heat transfer capability compared to the former plain inner tube wall. Due to the multiplied effects of the tubes outside fins and inner spiral ridges, a high coefficient for overall heat transfer is observed. |

Features : 2. High Heat Transfer Performance |

| Applications: 1. Turbo Refrigerator 2. Boilers 3. Heat exchangers for petrochemical industry 4. Screw refrigerators 5. Absorption Type refrigerators |

| Material Used: Copper C12200 |

Technical Specifications of Internal Ridges |

|

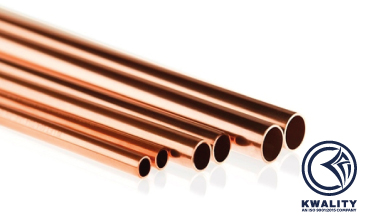

Integral Fin Tubes

Integral fin tubes were developed to increase the heat transfer performance of fluids while reducing the physical size and cost of the heat exchanger. In these tubes the fins are rolled out from the wall of the tubes and hence are integral with the tube. As the fins are formed from the base tube by rolling out material from its wall, the wall thickness under the finned section is reduced compared to the wall thickness at plain ends. These fin tubes can be manufactured from most tubular materials and the hardness of the material usually determines the finning code or fin profile. The harder materials such as Nickel Alloys, Stainless Steel, Titanium are supplied with higher density (i.e 26,28,30 or 36 FPI). This shallow profile reduces the work hardening of the material and helps eliminate the possibility of root fin cracking.

Whereas, with softer materials like Carbon Steel, Copper, and Copper Alloys are supplied with deeper profile giving a lower fin density (i.e 16 or 19 FPI).

These tubes can also be supplied with intermediate plain landing as well as U Bent, where the U Bend portion can be Finned or Un-Finned.

| PLAIN END | No.of Fins per Inch | FINNED SECTION | ||||||||

| Outside Dia (O.D) | Wall Thickness (T) | OD FD | FIN HT H +/-0.10 |

Root Dia RD | Inner Dia FID | Outside Area M/M |

Surface Area Ratio Outside/Inside (Approx). |

|||

| (mm) | (Inch) | (mm) | (SWG) | |||||||

The Fin Tubes can be supplied either in Straight or "U" Bend Form, and either in "As Finned Temper " or duly "Stress Relief Annealed ".

These Fin Tubes can be supplied duly inspected and approved by Third Party Inspecting Agencies like, Lloyds Bureau Veritas, PDIL, TUV, Baxcounsel, Etc.

To serve you more efficiently, please send us your specific Enquiry, indicating the following details :

1. Fin Tube Material

2. Outside Diameter

3. Wall thickness below finned portion

4. No.of Fins per Inch

5. Overall Length of the Tube

6. Length of Plain Tube Section at each intermediate / end.

7. Total Quantity required.

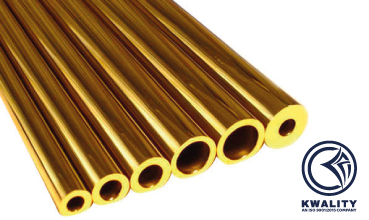

End Cross Tubes

END CROSS Tubes are a type of integral fin tubes, with very low fin profile in trapezoidal shape. These tubes are also called as high performance tubes due to their extended surface and are majorly used in Vapour Absorption Chillers. These tubes can be manufactured with plain inner tube surface or with Internal Ridges.

Materials Used: Copper, Copper Alloys Stainless Steel

Tube Size: 12.7mm OD upto 25.4mm OD (with minimum wall thickness of 0.5mm)